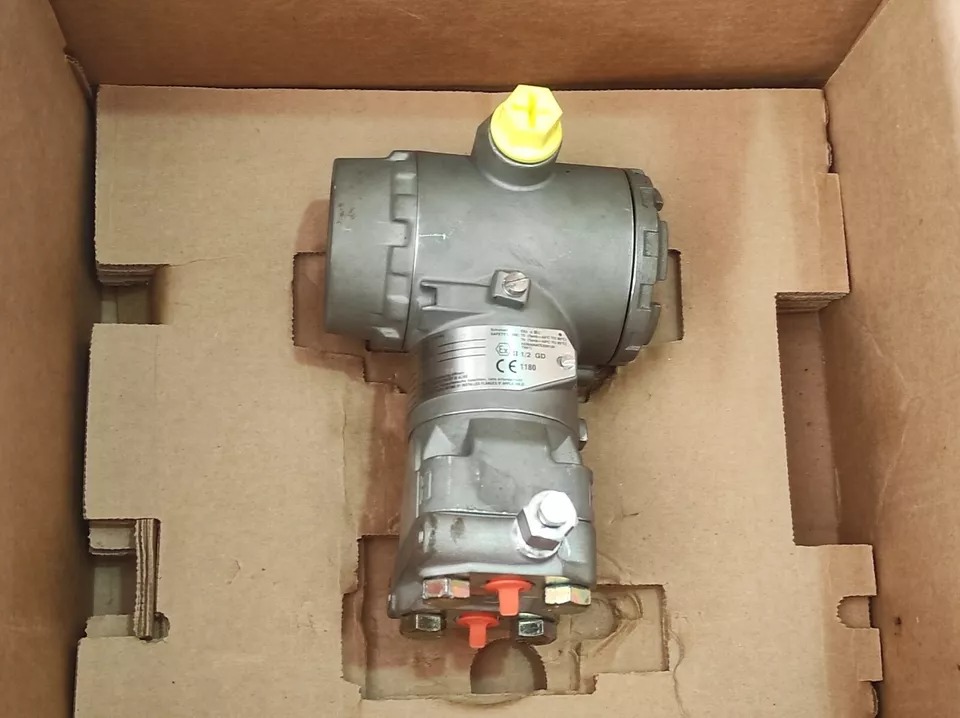

Rosemount 3051 CD0A02A1KH2S6E8L4M6P1Q4 Pressure Transmitter 3051CD

Rp123000.00

Description:

The Rosemount 3051CD Pressure Transmitter is an advanced, high-performance solution for measuring and controlling process pressures in industrial applications. It combines precision, reliability, and advanced diagnostics to ensure optimal performance in challenging process environments. Designed for oil & gas, chemical, power, water treatment, and other industrial sectors, the Rosemount 3051CD is suitable for use in critical applications that require accurate and real-time pressure measurements.

This transmitter provides digital communication capabilities, integrating seamlessly with plant control systems. With advanced diagnostics, it helps enhance uptime and reduce maintenance costs.

Key Features:

Differential Pressure Measurement: Provides highly accurate differential pressure measurement for various applications.

Advanced Diagnostics: Features such as AMS™ Device Manager diagnostics help improve predictive maintenance, reducing unplanned downtime.

Stability and Performance: Ensures long-term stability and high performance, even in fluctuating process conditions.

Flexible Output Options: Available with HART, Foundation Fieldbus, or Profibus DP communication protocols for integration with control systems.

Local Display: Option for a local display to provide process information in real-time.

Wide Range of Pressure Ranges: Suitable for a broad range of pressure applications with customizable pressure ranges.

Proven Rosemount Technology: Incorporates the Proprietary Rosemount Technology, providing unmatched accuracy and reliability in pressure measurement.

Technical Specifications:

Model: Rosemount 3051CD

Measurement Principle: Differential Pressure (DP)

Pressure Range: Customizable to fit application needs

Output: 4-20 mA, HART, Foundation Fieldbus, or Profibus DP

Power Supply: 12-42 V DC

Process Temperature: -40°C to +85°C (-40°F to +185°F)

Process Pressure: 0 to 15000 psi (varies by model)

Accuracy: ±0.065% of span

Stability: ±0.02% of URL

Display: Local display option available for real-time monitoring

Environmental Protection: IP67, NEMA 4X

Certifications: ATEX, IECEx, FM, CSA, CE

Communication Protocols: HART, Foundation Fieldbus, Profibus DP

Applications:

Oil and Gas: Measuring pressure in upstream, midstream, and downstream operations.

Chemical and Petrochemical: Accurate pressure measurement in reactors, distillation columns, and process vessels.

Water Treatment: Monitoring and control of pressure in water and wastewater systems.

Power Generation: Pressure measurement for boilers, turbines, and heat exchangers.

Food and Beverage: Ensuring pressure stability in processes such as pasteurization and bottling.

Advantages:

High Accuracy: Provides high precision and repeatability in pressure measurement.

Reliable Performance: Proven in demanding industrial environments, ensuring long-term reliability.

Flexible Integration: Easily integrates with existing control systems and plant management platforms.

Reduced Downtime: With advanced diagnostics, helps to identify issues before they affect operations, reducing unplanned downtime.

Wide Application Range: Suitable for various industries requiring differential pressure measurement and control.