Rosemount 114C Flanged Thermowell

Rp123000.00

The Rosemount 114C Flanged Thermowell is a heavy-duty, barstock thermowell designed to protect temperature sensors (such as RTDs or thermocouples) in demanding industrial processes. The 114C series ensures robust mechanical integrity and process compatibility, offering flexibility in mounting styles, materials, and customization to suit varied process conditions.

The flanged version conforms to industry standards for flange connections, ensuring reliable and secure installation in process piping or vessel nozzles. Built from solid barstock, it provides strength and integrity under pressure, temperature, and flow stress. Optional testing, such as hydrostatic pressure, dye-penetration, and material certification, ensures compliance with stringent industrial requirements.

The 114C Flanged Thermowell is widely used across sectors such as petrochemical, oil & gas, chemical processing, utilities, and general industrial temperature measurement applications.

Technical Specifications

Parameter / Attribute | Typical / Available Values / Notes |

Manufacturing standard (flange) | ANSI B16.5; flange-to-stem weld per ASME Section IX |

Weld options | Full penetration weld (F), Partial penetration weld (P), Forged/no-weld (G) |

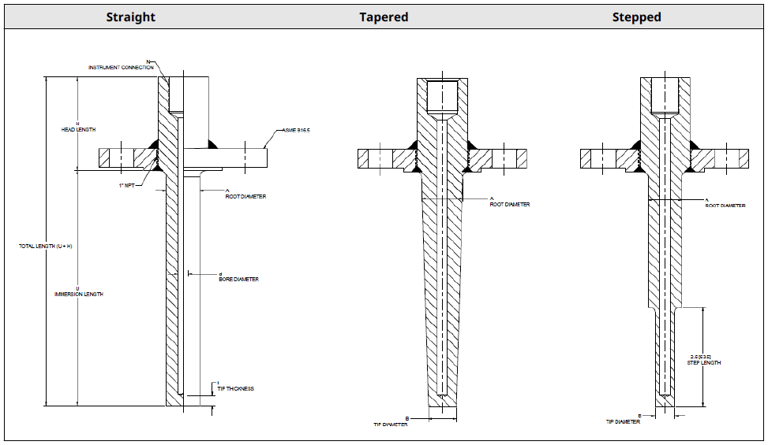

Stem styles | Straight, tapered, or stepped stems |

Thermowell materials | Stainless steel (316/316L, 304/304L), carbon steel (A105), exotic/corrosion-resistant alloys (Alloy C‑276, duplex, chrome-moly, nickel alloys, titanium, superduplex) |

Immersion length (U) | Customizable, from 25 mm (1 in) up to long lengths per application needs |

Instrument connection | Commonly ½‑14 NPT female; other threads possible |

Bore diameter / Tip wall / Tip diameter | Standard bore 6.6 mm; tip-wall thickness ~6.4 mm; customizable |

Certifications / Options | Material certification, optional NACE compliance, hydrostatic pressure test, PMI, NDT testing |

Wake Frequency Calculation (WFC) | Optional engineer-performed calculation to ensure compatibility with process flow and avoid vibration issues |

Surface finish | Standard 0.8 µm Ra; optional improved finish or electropolishing for high-corrosion or sanitary applications |