Groth Model 8800A Pressure/Vacuum Valve & Flame Arrester

Rp123000.00

Groth Model 8800A Pressure/Vacuum Valve & Flame Arrester

Product Description

The Groth Model 8800A is an end-of-line Pressure/Vacuum Relief Valve combined with a high-performance flame arrester. This integrated unit is engineered to protect storage tanks from overpressure or excessive vacuum while preventing flame propagation from external ignition sources. By utilizing cushioned-air seating and corrosion-resistant components, the 8800A ensures reliable sealing, reduced emissions, and enhanced fire safety.

The assembly consists of the Groth 1200A Pressure/Vacuum Relief Valve paired with the 7618 Flame Arrester. Its self-draining design, drip rings, and non-sticking fluoropolymer diaphragms provide dependable operation even in demanding conditions involving resinous vapors or moisture.

Key Features

Cushioned Air Seating for smooth and reliable valve operation.

Fluoropolymer Seating Diaphragms to minimize sticking caused by resinous vapors or atmospheric moisture.

Self-Draining Housing with Drip Rings to prevent condensate buildup and freezing.

Integrated Flame Arrester using a spiral-wound, crimped ribbon flame element for effective flame quenching.

Modular Construction for easier maintenance and component replacement.

Suitable for NEC Group D and IEC Group IIA gas service.

Pre-Ignition Pressure: Atmospheric.

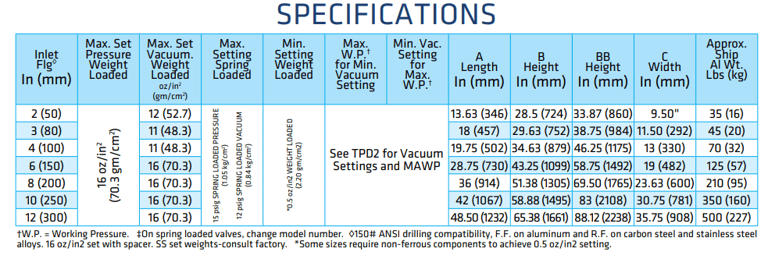

Technical Specifications

Sizes

2” (DN 50) to 12” (DN 300)

Pressure Relief Settings

0.5 oz/in² to 15 psig

Vacuum Relief Settings

0.5 oz/in² to 12 psig

Materials of Construction

Aluminum

Carbon Steel

Stainless Steel

Other special materials available upon request

Type

End-of-Line Pressure/Vacuum Valve with Flame Arrester

Flame Arrester Element

Spiral-wound, crimped ribbon design

Designed to prevent flame transmission from external ignition sources

Application

Storage tanks handling flammable vapors requiring both pressure/vacuum protection and fire safety.