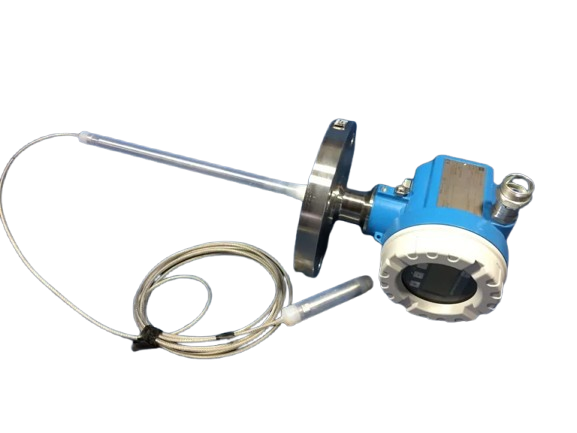

Endress+Hauser FMP41C-AEAGKB21A4A LevelFlex Guided Wave Radar Level Transmitter

Rp123000.00

The Endress+Hauser FMP41C-AEAGKB21A4A is a Guided Wave Radar (GWR) level transmitter designed for continuous, precise level measurement of liquids, slurries, and solids in a variety of industrial processes. The LevelFlex FMP41 series is highly reliable, offering robust performance even in challenging applications where other measurement technologies may fall short. This transmitter is particularly suited for high-precision, long-term measurement in industries such as chemical processing, oil and gas, water treatment, food and beverage, and more.

The FMP41C variant integrates advanced features and configurations, ensuring high accuracy and flexibility to meet the specific needs of your process. With HART communication and self-diagnostic capabilities, this device ensures continuous operation and easy integration into control systems.

Product Features

Guided Wave Radar Technology: Utilizes high-frequency radar waves that travel along the probe. These waves reflect back from the surface of the measured medium, enabling precise level measurements even in conditions with foam, vapor, or agitation.

Non-Contact Measurement: The guided radar technology ensures no physical contact with the process medium, reducing wear and maintenance needs and enhancing the durability of the sensor.

Wide Application Range: Ideal for liquids, slurries, and solids, making it versatile for various industrial sectors such as oil & gas, chemical processing, food & beverage, pharmaceuticals, and wastewater management.

Advanced Display and Diagnostics: The FMP41C features an integrated local display for real-time monitoring, setup, and diagnostics. Self-diagnostic capabilities ensure the device continuously monitors its operational health, alerting users to potential issues before they affect performance.

Robust Design: The transmitter is constructed to withstand harsh environmental conditions, including high pressures and temperatures, ensuring reliable operation in industrial settings.

Versatile Probe Options: Multiple probe configurations (coaxial, single rod, or twin rod) allow for customization to suit different application needs, with probe lengths up to 30 meters.

Temperature and Pressure Tolerance: Capable of operating at temperatures ranging from -40°C to 200°C (-40°F to 392°F) and pressures up to 40 bar (580 psi), suitable for a wide variety of process conditions.

Flexible Output Options: The device provides 4-20 mA output with HART communication as well as Profibus PA and FOUNDATION Fieldbus communication options for seamless integration into existing control systems.

Minimal Maintenance: With no moving parts, the FMP41C requires minimal maintenance, making it a cost-effective and low-maintenance solution for continuous level monitoring.

Specifications

Model: Endress+Hauser FMP41C-AEAGKB21A4A

Measurement Technology: Guided Wave Radar (GWR)

Frequency Range: 6 GHz

Accuracy: ±5 mm (typical)

Measuring Range: Up to 30 meters (depending on probe type and application)

Process Temperature: -40°C to 200°C (-40°F to 392°F)

Process Pressure: Up to 40 bar (580 psi)

Probe Types: Coaxial, single rod, or twin rod

Probe Length: Customizable, up to 30 meters

Process Connection: Flanged, threaded, or customized options

Display: Integrated local display for setup, operation, and diagnostics

Enclosure Rating: IP66/IP67 (or equivalent)

Power Supply: 24V DC (typical)

Output Signal: 4-20 mA with HART, Profibus PA, or FOUNDATION Fieldbus

Safety Certifications: ATEX, FM, CSA, IECEx (hazardous area approvals)

Self-Diagnostics: Continuous self-monitoring for performance assurance

Temperature Compensation: Automatic temperature compensation to ensure high accuracy

Applications

The Endress+Hauser FMP41C-AEAGKB21A4A LevelFlex is ideal for continuous level measurement in a range of challenging industrial environments:

Chemical Processing: Precise level measurement in reactors, storage tanks, and pipelines, even in volatile chemicals.

Oil & Gas: Monitoring levels in separators, storage vessels, and pipelines under high pressure and temperature conditions.

Water and Wastewater: Used in applications like clarifiers, sedimentation tanks, and sludge management for reliable level measurement.

Food and Beverage: For measuring liquids in fermenters, brewing tanks, and storage vessels.

Pharmaceuticals: Ensures consistent measurement in bioreactors, pharmaceutical tanks, and bulk storage vessels.

Power Generation: Level measurement in cooling towers, boiler feedwater tanks, and condensate recovery systems.

Mining and Metals: Ideal for slurry and solid level measurement in mineral processing and metal production.